Alabama’s CNC machining industry is known for its craftsmanship and innovation, especially when it comes to dealing with exotic materials and intricate designs. This skillset sets local CNC companies apart as they face the challenges of machining high-strength alloys, unusual geometries, and complex patterns. These CNC experts rely on advanced technology and refined techniques to ensure precision and maintain material integrity. So, how do CNC machine companies in Alabama handle these challenges? Let’s dive into the specific strategies they use.

Table of Contents

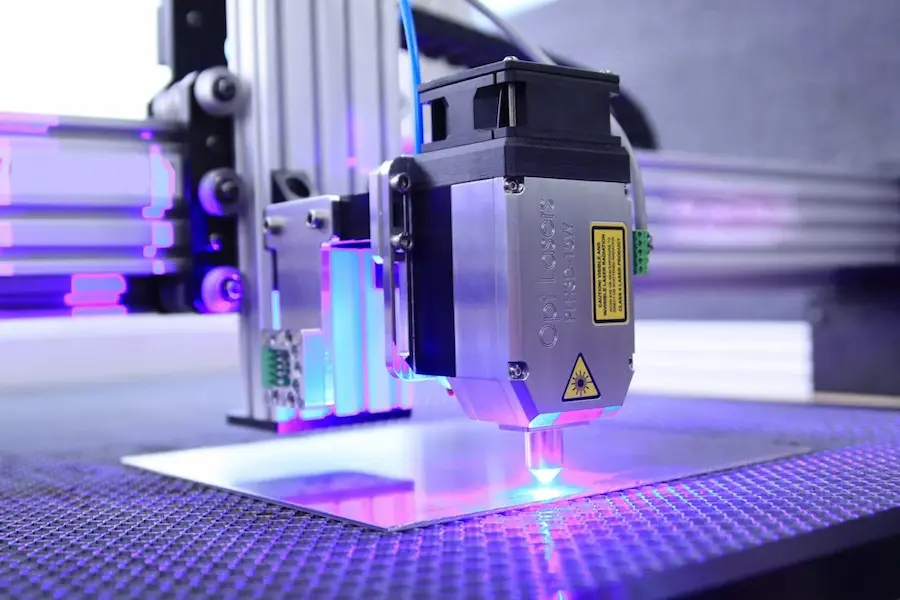

Utilizing Multi-Axis CNC Machines for Precision Cuts on Unusual Geometries

CNC machine companies in Alabama rely on multi-axis machines to handle complex shapes and unusual geometries. With machines that can operate on three, four, or even five axes, machinists can create intricate designs that wouldn’t be possible with traditional methods. This kind of advanced equipment allows for precise cuts and the ability to approach materials from multiple angles, ensuring a higher degree of accuracy.

The use of multi-axis CNC machines also means that these companies can take on more demanding projects. Whether it’s for the aerospace industry, medical devices, or automotive components, Alabama CNC machine companies manage to deliver exact specifications by manipulating cutting tools in precise paths. This versatility means better results for clients looking for high-quality, precision-driven machining solutions, no matter how complex the design.

Implementing Specialized Tooling to Tackle Hard-to-Cut Exotic Alloys

Machining exotic materials like titanium, Inconel, or hardened steel requires more than standard tools. Alabama CNC machine companies equip their machines with specialized tooling to address the challenges of these tough materials. Coated carbide tools, diamond-tipped cutters, and ceramic inserts are among the solutions used to maintain cutting efficiency and extend tool life when dealing with such demanding materials.

This specialized tooling not only enables precise cuts but also reduces the risk of tool breakage or damage to the workpiece. CNC machine companies in Alabama have learned to select the right tools based on the specific properties of the material—whether it’s heat resistance, hardness, or strength. With the right tools in hand, they can achieve cleaner cuts and maintain tight tolerances even with the most challenging alloys.

Adjusting Feed Rates and Spindle Speeds to Maintain Material Integrity

When machining exotic materials, maintaining material integrity is essential. Alabama CNC machine companies carefully adjust feed rates and spindle speeds to optimize cutting conditions. Slower feed rates and precise spindle speeds are often used to prevent overheating, minimize tool wear, and avoid material distortion, especially when working with materials prone to heat buildup.

By finding the right balance, these CNC companies can produce high-quality components without compromising the material’s properties. Whether it’s to prevent cracks in ceramics or manage chip formation in high-strength alloys, these adjustments ensure that each cut meets the exacting standards required in industries like aerospace, defense, and energy.

Applying Advanced Coolant Systems to Manage Heat on High-Performance Metals

Heat management plays a critical role in machining, particularly when working with high-performance metals that generate significant heat during cutting. Alabama CNC machine companies use advanced coolant systems to keep temperatures in check. These systems deliver a steady flow of coolant to the cutting area, helping to reduce friction, minimize thermal expansion, and improve the longevity of the tools.

Some CNC machine companies in Alabama go a step further by using high-pressure coolant systems that allow for deeper cuts and faster speeds, even when machining exotic alloys. These cooling methods not only prevent heat-related damage but also improve surface finish and part accuracy. Effective cooling makes a significant difference in quality, particularly when dealing with materials that demand tight tolerances.

Conducting Rigorous Prototyping to Refine Techniques for Complex Patterns

Before jumping into full-scale production, Alabama CNC machine companies invest time and effort into prototyping. This approach helps them refine techniques, test cutting strategies, and troubleshoot potential issues before moving on to the final production phase. Prototyping is especially important for complex patterns, where precision and accuracy are critical.

By conducting these tests, CNC companies can ensure that the final product meets all specifications, regardless of how intricate the design may be. This step not only improves the machining process but also saves time and reduces waste, as machinists can identify and correct any flaws during the prototype phase. It’s a smart, cost-effective way to perfect techniques, enhance quality, and meet customer requirements.